Ngikholwa ukuthi sivame ukuhlangana nesimo esinjalo.Uma uya enxanxatheleni yezitolo noma esuphamakethe uyothenga okuthile, uzobona ilebula elincane emkhiqizweni.Ilebula ingumugqa oqondile omnyama nomhlophe.Uma siya kokhokha, umthengisi usebenzisa okuthi Skena le lebula emkhiqizweni oneskena esibanjwa ngesandla, futhi intengo okufanele uyikhokhele lowo mkhiqizo iboniswa ngokushesha.

Ilebula yomugqa oqondile eshiwo lapha, igama lobuchwepheshe libizwa ngokuthi ibhakhodi, ukusetshenziswa kwayo okubanzi kwenza imishini yayo ehambisanayo yaziwe ngokushesha, futhi iphrinta yekhodi yebha njengenye yemishini ebalulekile yokusetshenziswa kwekhodi yebha isetshenziswa kabanzi ekukhiqizeni, kwezokuthutha nakwezinye izimboni. kudingeka ziphrintwe embonini yamalebula.

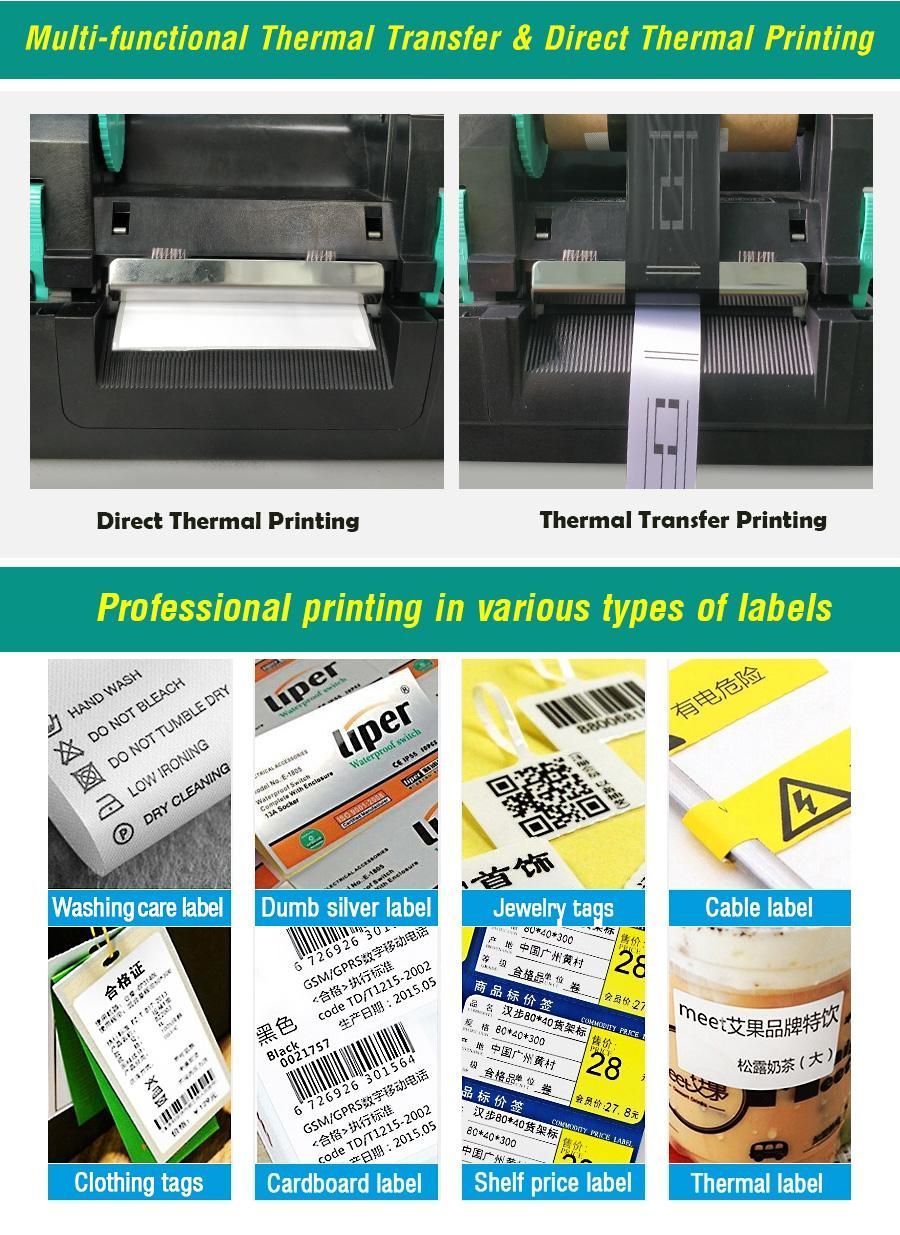

Iphrinta yebhakhodi iphrinta ekhethekile.Umehluko omkhulu phakathi kwamaphrinta ebhakhodi namaphrinta ajwayelekile ukuthi ukuphrinta kwamaphrinta ebhakhodi kusekelwe ekushiseni, futhi ukuphrinta kuqedwa ngeribhoni yekhabhoni njengendawo yokuphrinta (noma kusetshenziswa ngokuqondile iphepha elishisayo).Inzuzo enkulu yale ndlela yokunyathelisa uma iqhathaniswa nezindlela zokunyathelisa ezivamile ukuthi ukuphrinta Okuqhubekayo kwesivinini esikhulu kungafinyelelwa ngaphandle kokugadwa.

Okuqukethwe okuphrintwe iphrinta yebhakhodi ngokuvamile kuwuphawu lomkhiqizo wenkampani, ilogo yenombolo yomkhiqizo, ilogo yokupakisha, ilogo yebhakhodi, ilebula yemvilophu, ithegi yezingubo, njll.

Ingxenye ebaluleke kakhulu yephrinta yebhakhodi yikhanda lokuphrinta, elakhiwe nge-thermistor.Inqubo yokuphrinta iyinqubo yokushisa kwe-thermistor ukudlulisa i-toner ku-ribbon ephepheni.Ngakho-ke, lapho uthenga iphrinta yebhakhodi, ikhanda lokuphrinta liyingxenye efanele ukunakwa okukhethekile, futhi ukubambisana kwayo ne-carbon ribbon kuwumphefumulo wayo yonke inqubo yokunyathelisa.

Ngaphezu kwemisebenzi yokuphrinta yamaphrinta ajwayelekile, futhi inezinzuzo ezilandelayo:

1.Izinga lezinga lemboni, elinganqunyelwe inani lokuphrinta, lingaphrintwa amahora angama-24;

I-2.Ayinqunyelwe ngezinto zokunyathelisa, ingaphrinta i-PET, iphepha elihlanganisiwe, amalebula e-thermal self-adhesive, i-polyester, i-PVC nezinye izinto zokwenziwa kanye nezindwangu zelebula eziwashiwe;

I-3.Umbhalo kanye nehluzo eziphrintiwe ngokuphrinta kokudlulisa okushisayo kunomphumela wokulwa nokuqala, futhi ukunyathelisa okukhethekile kweribhoni yekhabhoni kungenza futhi umkhiqizo ophrintiwe ube nezici zokungangeni kwamanzi, ukulwa nokungcoliswa kwamanzi, ukubola nokubola kanye nokumelana nokushisa okuphezulu;

4.Ijubane lokuphrinta lishesha kakhulu, elisheshayo lingafinyelela amayintshi angu-10 (24 cm) ngomzuzwana;

5.Ingakwazi ukuphrinta izinombolo ze-serial eziqhubekayo futhi ixhume kusizindalwazi ukuze iphrinte ngamaqoqo;

6.Iphepha lelebula ngokuvamile lingamakhulu ambalwa amamitha ubude, elingafinyelela ezinkulungwaneni kuya ezinkulungwaneni zamalebula amancane;iphrinta yelebula ithatha indlela yokuphrinta eqhubekayo, okulula ukuyigcina nokuyihlela;

7.Ayivinjelwe indawo yokusebenza;

Ukuze uqinisekise ikhwalithi nokusebenza okuhle kwesikhathi eside kwephrinta yebhakhodi, idinga ukuhlanzwa njalo.

01

Ukuhlanzwa kwekhanda lokuphrinta

Ukuhlanza ikhanda lokuphrinta njalo futhi njalo, amathuluzi okuhlanza angaba ama-cotton swabs notshwala.Vala amandla ephrinta yebhakhodi, gcina inkomba efanayo lapho usula (ukugwema izinsalela zokungcola lapho usula emuva naphambili), phendulela ikhanda lokuphrinta phezulu, bese ukhipha iribhoni , ilebula iphepha, sebenzisa i-swab kakotini (noma indwangu kakotini) ocwiliswe isisombululo sokuhlanza ikhanda lokuphrinta, bese usula ngobumnene ikhanda lokuphrinta lize lihlanzeke.Bese usebenzisa i-swab kakotini ehlanzekile ukuze usule ngobumnene ikhanda lokuphrinta.

Ukugcina ikhanda lokuphrinta lihlanzekile kungathola imiphumela emihle yokuphrinta, futhi into ebaluleke kakhulu ukukhulisa impilo yekhanda lokuphrinta.

02

Ukuhlanza Nokugcinwa Kwe-Platen Roller

Kuyadingeka ukuhlanza njalo ibhakhodi iphrinta glue stick.Ithuluzi lokuhlanza lingasebenzisa i-cotton swabs kanye notshwala ukugcina induku yeglue ihlanzekile.Futhi ukuthola umphumela omuhle wokuphrinta nokwandisa impilo yekhanda lokuphrinta.Phakathi nenqubo yokunyathelisa, iphepha lelebula lizohlala phezu kwenduku yeglue.I-powder encane eningi, uma ingahlanzwa ngesikhathi, izolimaza ikhanda lokuphrinta;induku yeglue isetshenziswe isikhathi eside, uma kukhona ukugqoka noma ukungalingani okuthile, kuzothinta ukuphrinta futhi kulimaze ikhanda lokuphrinta.

03

Ukuhlanza ama-roller

Ngemuva kokuhlanza ikhanda lokuphrinta, hlanza ama-rollers nge-cotton swab (noma indwangu yekotini) efakwe ku-75% utshwala.Indlela yokwenza iwukuzungezisa isigubhu ngesandla ngenkathi ukhuhla, bese usomisa ngemva kokuba sihlanzekile.Isikhathi sokuhlanza sezinyathelo ezimbili ezingenhla ngokuvamile sikanye njalo ezinsukwini ezintathu.Uma iphrinta yebhakhodi isetshenziswa njalo, kungcono ukuthi kube kanye ngosuku.

04

Ukuhlanza isitimela sokushayela kanye nokuhlanza indawo ebiyelwe

Ngenxa yokuthi iphepha lelebula elijwayelekile liyazinamathela, i-adhesive kulula ukunamathela ku-shaft kanye nesiteshi sokudlulisa, futhi uthuli luzothinta ngokuqondile umphumela wokunyathelisa, ngakho-ke udinga ukuhlanzwa njalo.Ngokuvamile kanye ngesonto, indlela iwukusebenzisa i-swab kakotini (noma indwangu kakotini) efakwe otshwaleni ukuze kusule ingaphezulu le-shaft ngayinye yokudlulisela, ingaphezulu lesiteshi nothuli ku-chassis, bese uyomisa ngemva kokuhlanza. .

05

Ukuhlanza inzwa

Gcina inzwa ihlanzekile ukuze amaphutha ephepha noma amaphutha eribhoni angenzeki.Inzwa ihlanganisa inzwa yeribhoni kanye nenzwa yelebula.Indawo yenzwa iboniswa emiyalweni.Ngokuvamile, ihlanzwa kanye njalo ezinyangeni ezintathu kuya ezinyangeni eziyisithupha.Indlela yokusula ikhanda lenzwa nge-cotton swab efakwe utshwala, bese uyomisa ngemva kokuhlanza.

06

Ukuhlanza umhlahlandlela wephepha

Ngokuvamile ayikho inkinga enkulu nge-groove ye-guide, kodwa ngezinye izikhathi ilebula inamathela ku-guide groove ngenxa yezinkinga zekhwalithi ezenziwe ngumuntu noma ilebula, kuyadingeka futhi ukuyihlanza ngesikhathi.

Isikhathi sokuthumela: Aug-11-2022